Researchers from RMIT University in Australia, in collaboration with Tescan Group in Czechia and the University of North Texas in the USA, have developed novel bainitic titanium alloys (Ti-Cu-Fe) designed specifically for Additive Manufacturing (AM). This breakthrough has the potential to significantly improve the quality and performance of components produced through AM, particularly in industries that require high-strength materials.

Advancements in Alloy Design for Additive Manufacturing

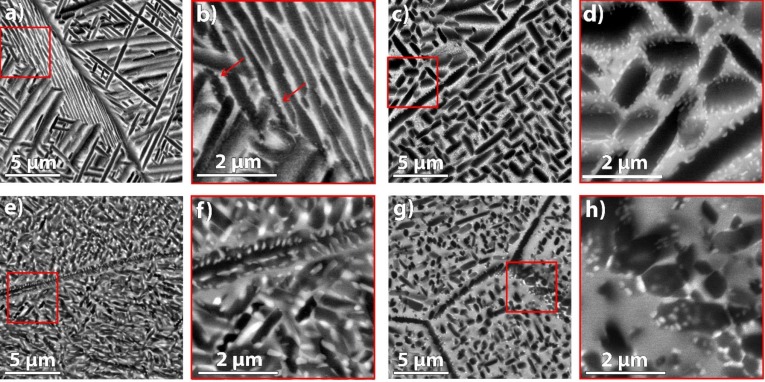

The study, published in *Materials & Design*, focuses on leveraging constitutional supercooling in Ti-Cu-Fe alloys to suppress the growth of large columnar grains, a common challenge in AM titanium alloys. This process allows for the formation of a refined, equiaxed grain structure, which is essential for improving the mechanical properties of the material.

Using Directed Energy Deposition (DED), a specific type of Additive Manufacturing, the researchers successfully manipulated the solidification microstructure. This method resulted in a bainitic microstructure characterized by an α-phase, Ti2Cu intermetallic phase, and a retained β-phase matrix. Such a microstructure is highly beneficial as it enhances the strength and durability of the material, making it more suitable for demanding applications.

Potential Applications and Future Research

The Ti-Cu-Fe alloy system developed by the researchers holds significant promise for further enhancing mechanical properties through grain boundary engineering and the introduction of additional nucleation sites. This potential improvement could lead to the production of even stronger and more resilient components.

The implications of this research are substantial, particularly for industries such as aerospace, automotive, and biomedical sectors, where high-performance materials are crucial. The use of low-cost elemental powders in combination with advanced manufacturing techniques like DED could also make this technology more accessible and cost-effective.

Final Thoughts

In summary, the development of these novel bainitic titanium alloys represents a significant step forward in Additive Manufacturing. By addressing key challenges in the microstructure of AM-produced components, this research opens up new possibilities for creating materials with superior mechanical properties. As the field of Additive Manufacturing continues to grow, innovations like these will play a crucial role in shaping its future.

For those interested in a more in-depth understanding of the research, the full study is available here.

Source: metal-am.com