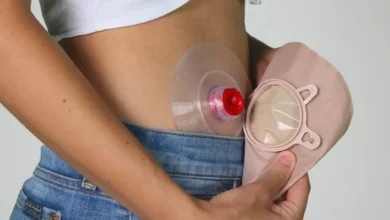

BIO INX, a top material developer for 3D bioprinting, has signed a strategic deal with Rousselot, a global leader in gelatin-based solutions. The partnership aims to make cutting-edge materials more accessible to researchers worldwide, facilitating the integration of Rousselot’s X-Pure gelatin biomaterials into BIO INX’s offerings.

A key highlight of the collaboration is the introduction of the X-Pure version of GEL-MA INX, BIO INX’s extrusion bioink, which enables the printing of constructs with living cells. This innovation, developed in tandem with Rousselot, aligns with BIO INX’s mission to simplify bioprinting processes. By enhancing reproducibility and adhering to stringent quality standards, this collaboration brings 3D bioprinting closer to clinical applications.

The roots of this collaboration trace back to the Polymer Chemistry and Biomaterials Group at Ghent University, where the original Gelatin Methacryloyl (GEL-MA) was pioneered 25 years ago using Rousselot gelatin.

“This collaboration represents the culmination of years of shared vision and innovation between BIO INX and Rousselot to increase standardization and quality in biomaterials for tissue engineering and 3D bioprinting,” said Jasper Van Hoorick, CEO of BIO INX.

“By integrating Rousselot’s X-Pure gelatin biomaterials into our portfolio and introducing a GMP-like bioink, we are not only advancing the capabilities of 3D bioprinting but also building further on our roots and the groundbreaking work of the research group at Ghent University prior to incorporation.”

The collaboration between BIO INX and Rousselot represents a pivotal advancement in 3D bioprinting, bringing together expertise and innovation to propel the field towards greater standardization and quality in biomaterials for tissue engineering and clinical applications.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.